Researchers find strong candidate for bone-friendly dental implants in heat-tempered magnesium alloy

Researchers testing a magnesium alloy in a process called T-5 tempering have determined that clinical application of T-5 magnesium (which has mechanical properties similar to titanium) fares well in high-stress applications. Its resorbable properties promote bone formation and healing with limited risk of infection. A key thought from the study is to develop nonabsorbable dental implants with permanent, supportive qualities or ones that are absorbable, similar to sutures.

A promising alternative is magnesium, a safely biodegradable metal and cofactor for many enzymes in DNA repair that also promotes bone health. But while its physical properties make it suitable for load-bearing sites, such as the temporomandibular region of the jaw, its rapid breakdown in the body sometimes results in the formation of hydrogen bubbles that can lead to serious complications.

In a unique collaboration, researchers at the NYU Tandon School of Engineering, NYU School of Medicine, and NYU Dentistry are developing and testing alloys of magnesium that are treated to improve strength and slow down the degradation process, thereby avoiding the formation of these bubbles.

In research published in the Journal of Cranio-Maxillofacial Surgery, the team, which includes Nikhil Gupta, associate professor of mechanical and aerospace engineering at NYU Tandon; Paulo Coelho, the Dr. Leonard I. Linkow Professor at NYU Dentistry; Eduardo D. Rodriguez, Helen L. Kimmel Professor of Reconstructive Plastic Surgery and chair, Hansjörg Wyss Department of Plastic Surgery at NYU School of Medicine; and Andrea Torroni, MD, associate professor, Wyss Department of Plastic Surgery at NYU School of Medicine, reported on their tests of a magnesium alloy that was subjected in Gupta’s lab to a process called T-5 tempering, involving heating at 210 degrees Celsius for 48 hours.

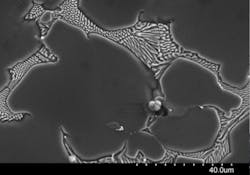

After surgically implanting small samples of the alloy in the fronto-nasal region of study animals, the team examined the accumulation of the element in the lymph nodes, finding no difference between animals with no implants and the study animals. The researchers also implanted untreated—or “as-cast”—alloy, finding that both the as-cast samples and T-5 heat-treated alloys showed good biocompatibility and promoted bone growth in test animals. The T-5 alloy, however, was much more stable, with an eight-fold lower degradation rate than the as-cast alloy.

Gupta said he was not surprised by the positive results, as they mirrored what he had observed during in vitro studies at NYU Tandon.

“In our lab we put both as-cast and the heat-treated alloy in a solution of sodium chloride to simulate body fluid environments. Not surprisingly, the as-cast version corroded a lot. However, the heat-treated version did not corrode at all,” he said. “What we have discovered is that by employing heat treatment we can change the alloy completely from a degradable, resorbable structure to one that doesn’t degrade over time. In essence, heat treatment makes magnesium behave, in vitro and in vivo, more like titanium.”

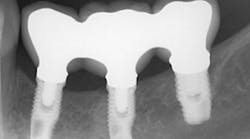

Torroni thinks the results auger well for eventual clinical applications of T-5 magnesium, whose mechanical properties are comparable to titanium, even in mandibular fractures, where stress on bone is particularly high. “The T-5 is really the best candidate for these high-stress applications. It has superior properties that are very close to those of bone and is very good for fixation of fractures,” he explained. “It exhibits lower long-term risks because it resorbs. And it can promote bone formation and bone healing. It is totally biocompatible with no risk of rejection, and limited risk of infection.”

The team also discerned no postsurgical morbidity, even in the control animals that received implants of untreated magnesium.

“Because of magnesium’s systemic absorbability, this is not a problem,” said Coelho. “The key idea is to make an implant that can be either nonabsorbable, as a permanent support, or absorbable, like sutures that go away after some time.”

Gupta said that the research would not have been possible without collaboration between NYU institutions. “The breadth of this research takes it from the lab all the way to a clinical setting,” he added.

This work was partially supported by the US Army Research Laboratory.

“Biocompatibility and degradation properties of WE43 Mg alloys with and without heat treatment: in-vivo evaluation and comparison in a cranial bone sheep model” is available at this link.

For more information about the New York University Tandon School of Engineering, visit their website.

For more information about NYU School of Medicine, visit their website.

For more information about NYU College of Dentistry, visit their website.